Thermal Camera Drone Roof Inspections

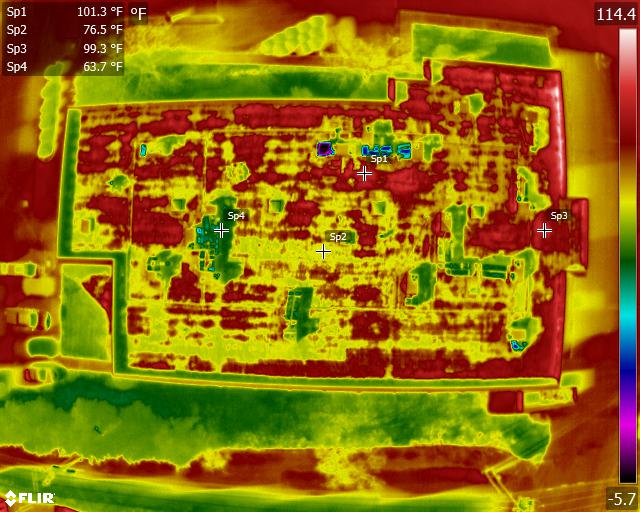

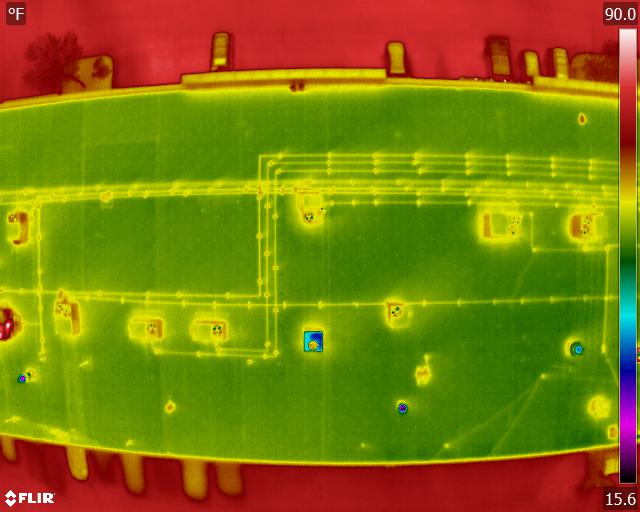

We utilize infrared thermal equipped drones to perform camera inspections of commercial, flat, roofing membranes, including EPDM, TPO, and PVC. We can inspect your entire roof, and let you know which specific areas are leaking and require repairs and/or replacement. It is often unnecessary to replace an entire roof.

We also provide periodic maintenance-scans for membrane roofs. These scans prevent small problems from becoming large, expensive problems.

About Our Infrared Thermal Camera Equipped Drone Inspections

John is an FAA-licensed drone pilot. He has an FAA-issued Daylight-Operations-Waiver, which allows him to legally fly nighttime missions. He also has an FAA-issued Airspace Authorization, which permits legal flights in controlled, Class C, Lexington airspace.

Utilizing an industrial drone equipped with an infrared camera, John performs non-invasive inspections and assessments of flat, membrane roofs including EPDM, TPO, and PVC.

Before the advent of infrared-drone technology, membrane roofs were destructively inspected with one-square-inch core samples. Alternatively, non-destructive methods were available utilizing nuclear density gauges, dielectric capacitance meters, or handheld infrared cameras. These methods require someone to physically walk a roof and take a small sample every ten-square-feet. These methods are time consumptive, costly, and leave the majority of a roof unassessed.

How does an infrared-camera-equipped drone identify areas of leakage? During daylight hours, solar loading occurs within a roof membrane and the insulation and/or decking beneath the membrane. At the end of the day, when the sun goes down, the membrane begins to cool. The underlying insulation and/or decking if wet, have higher masses and higher densities. These materials release heat at a much slower rate. Because of these differences in emissivity, infrared thermography will detect wet areas created by leaks because the wet areas will be warmer than the lower density, dry areas.

By utilizing infrared technology, the owner of a building can replace or repair only those areas of a roof that have failed, rather than being forced to replace an entire roof, which can prove exceedingly costly.